Purpose: To learn how the reader controller processes original

image read by the CIS

1. Overview

Original image read by

the CIS is processed by the reader controller, and then is sent to the main

controller. The reader controller converts the analog signal sent by the CIS

into the digital signal. Also, it evens image density level.

The image processing consists of the following 3 steps.

The image processing consists of the following 3 steps.

1) Analog image processing

2) A/D conversion

processing

3) Shading processing

The flowchart of image processing and details

of each step are shown below.

|

Step

|

Item

|

Detail

|

|

1

|

Analog image

processing

|

To perform image processing of the analog

signal (voltage value signal) output from the CIS.

1) Gain Correction: To

uniform gain of the analog signal.

2) Offset Correction: To

uniform output voltage of places where there is no incoming

light.

|

|

2

|

A/D Conversion

|

To convert the analog signal into the digital

signal corresponding to voltage value of each pixel

|

|

3

|

Shading

processing

|

To uniform density

level by correcting reading image density based on density measurement with the

standard while plate

This is performed each time 1 line is scanned. |

|

Image processing

system

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

<Purpose>

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

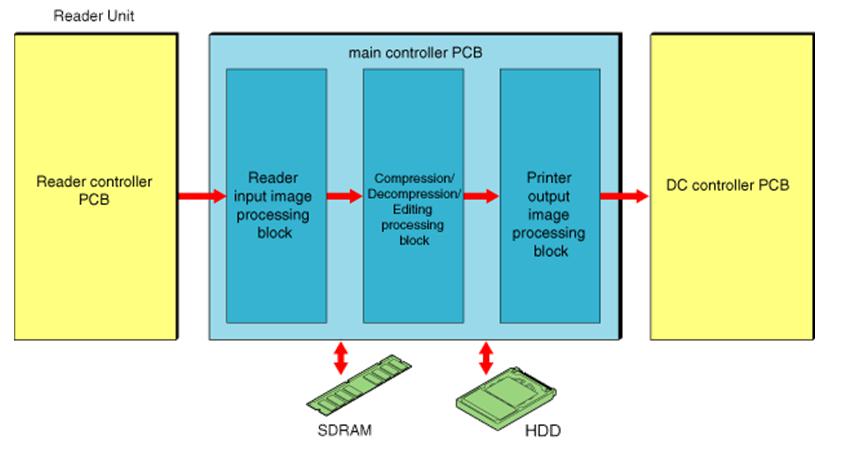

Purpose: To learn about the outline of the image processing

system, such as the components or the specifications.

1. Outline

In the image processing system, the

data sent from reader unit or external devices are converted into the format for

printing. The main controller PCB

handles data processing. The main

controller converts the data sent from reader unit or external devices into the

video signals and sends them to the DC controller PCB. See the components of the image processing

system below.

2. Specifications list of the image processing

system

Specifications in the image processing system are as

follows.

Main Controller PCB

Flow of the image data

Purpose: To learn about how the

image data flow in the main controller.

1. Outline

The main controller handles most of the image processing in this

copier.

The main controller is divided into the

following three main blocks.

1) Reader input image processing block

2) Compression/Decompression/Editing processing block

3) Printer output image processing block

Let’s learn each block next.

2. Reader input image processing block

In this block, image processing of the data

sent from the reader unit is done.

The image data read in the reader unit are converted in this block

from 8bit image density signal (multilevel) into 1bit image density signal

(binary), which is most suitable for printing.

See the data flow in this block

below.

3. Compression/Decompression/Editing processing block

In this block,

the image data sent from reader input image processing block are compressed,

decompressed and edited. The image data,

which are binarized in the reader input image processing block, are converted to

suitable data based on the information, such as density, magnification or page

layout, set on the control panel.

See the data flow in this block below.

4. Printer output image processing block

In this block,

the image data sent from compression/decompression/editing processing block are

processed and sent to the DC controller.

The image data density is adjusted appropriately and the data resolution is converted by smoothing. See the data flow in this block below.

4. Printer output image processing block

In this block,

the image data sent from compression/decompression/editing processing block are

processed and sent to the DC controller.

The image data density is adjusted appropriately and the data resolution is converted by smoothing. See the data flow in this block below.

Thickening processing is to thicken thin

lines forcefully so that the printed line cannot fade to disappear, for

instance, when it is reduced-printed.

Service Tasks

○Purpose: To learn about what the service person should do in order to maintain

the product quality.

●Outline

The works service person does concerning image processing system are

shown in the below table.

You can see the concrete description by clicking each

item.

1. Parts replacement

Necessary works to replace parts are as follows.

■Main controller PCB

When the main controller PCB is replaced, remove following parts from

the demounted main controller PCB and mount them on new PCB.

1) Boot ROM

2) HDD

3) SDRAM

4) Counter memory

Do not replace the HDD or main

controller unless it is damaged because user setting information or used data is

written in them.

2. Maintenance service

N/A

3. Troubleshooting

Refer to the chapter of Self-diagnosing in

the service manual of the iR4570/3570/2870/2270 series.

4. Important instructions for servicing work

N/A

1. Part

Replacement

The following parts require adjustment in

service mode or counter clearing after part replacement.

Their adjustment procedures are as follows.

■Contact Image Sensor (CIS)

Unit

After replacing the CIS

unit, enter a number described on the label on the CIS unit to the following

service mode item.

∙COPIER > ADJUST > CCD

> MTF-MG

■Reader Controller PCB

A. Handling before

replacing the reader controller

If the ADF is already attached, output

P-PRINT in service mode before replacing the part.

∙COPIER > FUNCTION > MISC-P > P-PRINT

B. Handling after

replacing the reader controller

1. Reader

controller-related adjustment

Follow the steps

below.

1) Download the latest

system software (R-CON) using SST.

2) Clear RAM in service

mode. Then, turn the main power OFF and ON.

∙COPIER >

FUNCTION > CLEAR > R-CON

3) Enter values of the

items below in service mode.

a. Values on the

service label (inside the reader left cover)

a-1. CIS reading

position adjustment (fixed reading)

∙COPIER >

ADJUST > ADJ-XY > ADJ-X

a-2. Position

adjustment in the main scan direction (fixed reading)

∙COPIER

> ADJUST > ADJ-XY > ADJ-Y

a-3. Shading position adjustment (fixed

reading)

∙COPIER

> ADJUST > ADJ-XY > ADJ-S

a-4. MTF value in the

main scan direction

∙COPIER

> ADJUST > CCD > MTF-MG

If a value of COPIER >

OPTION > BODY > CCD-LUT is other than 0 before the reader controller PCB

is replaced, it is necessary to set a number other than 0 again and perform the

following adjustment using the D-10 chart (RY9-9129-000).

∙COPIER >

FUNCTION > CCD > LUT-ADJ2

2. ADF-related

adjustment

The machine stores

ADF-related service data in the reader controller RAM. Therefore, the ADF must

be adjusted when the reader controller is replaced or the RAM is

cleared.

Enter values of P-PRINT that has been output in the following service mode items.

a. Position adjustment

in the main scan direction (stream reading)

∙COPIER

> ADJSUT > ADJ-XY > ADJ-Y-DF

b. Document stop

position adjustment

∙FEEDER >

ADJSUT > DOCST

c. Document feed speed

(scaling) adjustment

∙FEEDER > ADUST >

LA-SPEED

Perform adjustment using

the following items.

a. Tray width

adjustment

∙FEEDER

> FUNCTION > TRY-A4

∙FEEDER

> FUNCTION > TRY-A5R

∙FEEDER > FUNCTION > TRY-LTR

∙FEEDER

> FUNCTION > TRY-LTRR

b. CIS reading

position adjustment (stream reading)

∙COPIER

> FUNCTION > INSTALL > STRD-POS

c. White level

adjustment

∙COPIER >

FUNCTION > CCD > DF-WLVL1

∙COPIER

> FUNCTION > CCD > DF-WLVL2

After the above

adjustment items are all ended, store the P-PRINT [1] that has been output in

the service bookcase, and dispose of the previous P-PRINT.

2. Maintenance Service

Cleaning of the copyboard

glass and the ADF document reading area.

Use silicone oil (FY9-6013-000) and cleaning paper (FC5-4430-000) to clean the copyboard glass. Take the steps below.

1) Wipe the reading glass with dry cleaning

paper.

2) Push the silicone oil bottle 2 or 3 times

to moisten the cleaning paper.

3) Apply silicone oil to the reading glass

with the cleaning paper. Silicon oil must be applied evenly at this

time.

4) Use a fresh and dry face of the cleaning

paper (i.e., the area where silicone oil is not moistened) to wipe the reading

glass.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3. Troubleshooting

■White/Black streaks

The copyboard glass or/and the standard white

plate gets soiled. Clean the parts.

∙Copyboard glass: Follow the steps described in [2. Maintenance

Service] to clean.

∙Standard white plate: Wipe the white plate using alcohol or a cloth

moistened with water, and then wipe the plate with a dry

cloth.

4. Points to note

on servicing

When the CIS unit is moved with hands, do not

hold the CIS unit directly but hold the carriage belt.

0 Reviews:

แสดงความคิดเห็น