Service

Tasks

○Purpose : Here, we will learn about the various tasks the service person is

expected to carry out to perform for the purpose of maintaining a specific level

of machine performance.

●Outline

Let’s take a look at the tasks of the service

person associated with the fixing system. To obtain a detailed description,

click the appropriate item.

|

1. Parts Replacement

Some parts of the machine require adjustment

or counter initialization in service mode upon replacement. If you have replaced

any of the following, go through the steps given:

■Fixing Film Assembly

If you have replaced the fixing film

assembly, you will have to reset the fixing film assembly life counter so that

the count will start anew.

Make the following selections in service mode

to reset the counter:

COPIER > COUNTER > DRBL-1 >

FX-FILM

■Pressure Roller

If you have replaced the pressure roller, you

will have to reset the pressure roller life counter so that the count will start

anew.

Make the following selections in service mode

to reset the counter:

COPIER > COUNTER > DRBL-1 >

FX-LW-RL

■Fixing Cleaning roller

If you have replaced the fixing cleaning

roller, you will have to reset the fixing cleaning roller life counter so that

the count will start anew.

Make the following selections in service mode

to reset the counter:

COPIER > COUNTER > DRBL-1 >

FX-CL-RL

■Pressure roller

bushing

If you have replaced the pressure roller

bushing, you will have to reset the pressure roller bushing life counter so that

the count will start anew.

Make the following selections in service mode

to reset the counter:

COPIER > COUNTER > DRBL-1 >

FX-LW-BR

Each life count is kept in memory on the DC

controller PCB. If you have to replace the DC controller PCB, be sure to enter

the count that has been read of the previous PCB.

2. Maintenance

Servicing

The service person is expected to replace,

clean, or check the following at specific intervals; perform the work when the

end of individual intervals approach:

| Item | Parts name |

Task

|

Approximate

interval

|

Remarks

| |

| Periodically replaced parts | - | - | - | The fixing assembly does not have parts that must be replaced periodically. | |

| Durables | Fixing film unit |

iR2270/2870

|

replace

|

every 150,000 prints

|

|

|

iR3570/4570

|

replace

|

every 240,000 prints

|

|||

| Pressure roller |

iR2270/2870

|

replace

|

every 150,000 prints

|

||

|

iR3570/4570

|

replace

|

every 240,000 prints

|

|||

| Fixing cleaning roller |

iR2270/2870

|

replace

|

every 150,000 prints

|

||

|

iR3570/4570

|

replace

|

every 240,000 prints

|

|||

| Pressure roller bushing |

replace

|

every 300,000 prints

|

|||

| Periodical serving | Fixing inlet guide |

clean

|

every 120,000 prints

|

Dry wipe with lint-free

paper.

| |

| Film bias static eliminator | iR2270/2870 | clean | every 150,000 prints | Dry wipe with lint-free paper. | |

| iR3570/4570 | clean | every 240,000 prints | Dry wipe with lint-free paper. | ||

3.

Troubleshooting

■E000 through 003 (fault in fixing

assembly)

If a fault occurs in the fixing assembly, go

through the following: (You will have to reset the error code after performing

these steps.)

1) replace the fixing film unit.

2) check the connectors between the fixing film unit and the DC

controller.

3) replace the DC

controller PCB.

■E007-0000 (fixing film rotation

error)

If a fault occurs in the rotation of the

fixing film, go through the following to correct it. (You will need to reset the

machine after performing these steps.)

1) check the machine as a whole, and check particularly the gear used to

drive the pressure roller of the fixing assembly; then, replace any damaged

part.

2) check the marker of the fixing film; if soiled or damaged, clean with

lint-free paper or replace the fixing film unit.

3) check the connectors between the fixing film speed sensor (PS8) and

the DC controller.

4) replace the fixing film speed sensor

(PS8).

5) replace the DC controller PCB.

■Setting Fixing Film Cleaning

Intervals

By default, the machine cleans the fixing

film only in the event of a jam; nevertheless, you can change the intervals by

making the following selections in service mode so that the machine will clean

the film regardless of jam removal:

COPIER > OPTION > BODY > FIX-CON

(Category 2)

0: clean only in response to jam (default)

1: clean during last rotation every 500 prints

2: clean during last rotation every 200 prints

3: clean during last rotation every 100 prints

■Soiling at Specific

Intervals

The presence of a scratch or dirt on a roller

of the fixing assembly will show up as a cyclic fault in output images. You can,

therefore, identify the cause of a cyclic fault based on the interval of its

occurrence.

If a cyclic fault is noted, consult the

following table to identify the cause (roller).

|

Parts name

|

Image fault

|

Interval

|

Remedy

| |

|

Fixing film

|

soiling at specific

interval

(face of paper)

|

76 mm (approx.)

|

Clean or replace the fixing film

unit.

| |

|

Pressure roller

|

soiling at specific

intervals

(back of paper)

|

iR2270/2870

|

79 mm (approx.)

|

Clean or replace the pressure

roller.

|

|

iR3570/4570

|

95 mm (approx.)

| |||

|

Delivery roller

|

Soiling at specific

internals

(face of paper)

|

42 mm (approx.)

|

Clean or replace the delivery

roller.

| |

4. Points to Note About

Servicing

■When Handling the Fixing

Assembly

∙Be sure to turn off the power before removing the fixing

assembly.

The fixing assembly is extremely hot immediately after printing. Be

sure to leave the machine alone for some time before touching the fixing

assembly.

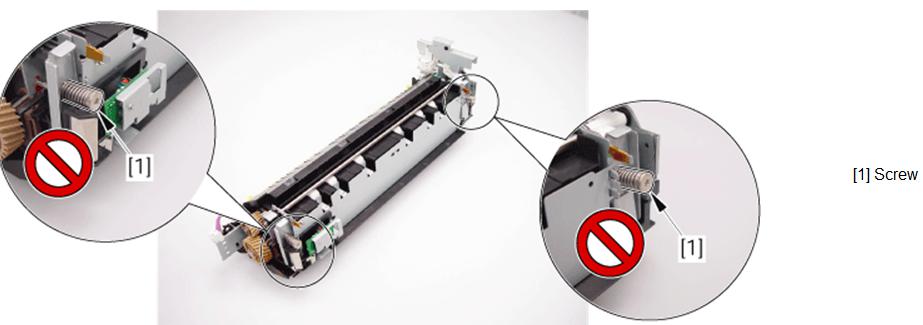

∙Do not ever turn the screw used to lock the fixing film

in place. Otherwise, the nip pressure will be affected, possibly leading to

fixing faults and jams.

■Points to Note When Handling the Fixing Film

Unit

∙ Do not disassemble the fixing film unit in the

field.

∙ Do not touch the surface of the fixing film, and take care not to

damage it.

■Resetting Error Codes

If a fault indicated by a jam code E000

thorough E003 (fault in the fixing assembly) occurs, merely turning off and then

on the main power switch will not reset the machine. Make the following

selections in service mode to reset the machine:

1) remove the causes of the error.

2) in service mode, make the following selections, and press the OK

key.

3) turn off and then on the power switch.

■Compatibility of the Fixing

Assembly

The fixing assembly of the iR2270/2870 Series machine

and that of the iR3570/4570 Series machine are not compatible.

You will not be able to physically install the wrong assembly because of the difference in the number of pins on the AC connector. Check the number of pins before fitting a fixing assembly into the machine.

You will not be able to physically install the wrong assembly because of the difference in the number of pins on the AC connector. Check the number of pins before fitting a fixing assembly into the machine.

The iR2270/2870 Series machine and the

iR3570/4570 Series machine also differ in terms of assembly components as can be

learned from the following table:

| |||||||||||||

0 Reviews:

แสดงความคิดเห็น